How To Install Waterproof Led Strip Lights

How to Install LED Strip Lights? LED strip lighting installed for commercial brandish This is a detailed all-inclusive guide on LED strip light installation for DIY, professionals and amateurs alike. Information technology has everything you need to know about how to install LED strip lights. This guide elaborates on all the knowledge, methods, and notes worth of attention. It as well points out the common mistakes that many people would make. The LED strip installation guide includes the basic knowledge grooming, installation supplies and tools needed, and actual installation stride by footstep. The detailed steps covered include:

LED Strip Light Installation Guide: Step by Step Installation Instruction New to LED strip lights?

LED strip lights accept many advantages. They operate on 12V or 24V DC, a very safe depression voltage. They are flexible to form various shapes of lighting design and to be able to be applied on curved surface. With thin and apartment depression contour body, it is unique for strip lights to create lighting without seeing the lighting fixture. Strip lights are cuttable and linkable, and come with 3M double-sided back adhesive, making them very easy to be installed for indoor or outdoor applications. No matter for commercial or for residential, white LED strip lights are dandy for ambient lighting, emphasis lighting or tasking lighting. RGB and dream color strip lights are oft used to create atmosphere. In summary, strip lights take a wide range of applications and are perfect for DIY lighting projects. Due to the to a higher place advantages, LED strip lights have become more and more pop. Many users want to install strip lights by themselves, so they can actualize their great ideas of strip lighting. Information technology will be easy to exercise and then afterwards reading our LED strip light installation guide. Subsequently reading this spread-out guide, users are able to install strip lights like a professional person, making their wish or DIY strip lights come true. After reading this article, if you lot are still not sure about how to install, please seek professional assist. At present delight follow usa to encounter how to employ LED strip lights. This strip calorie-free installation guide includes three parts:

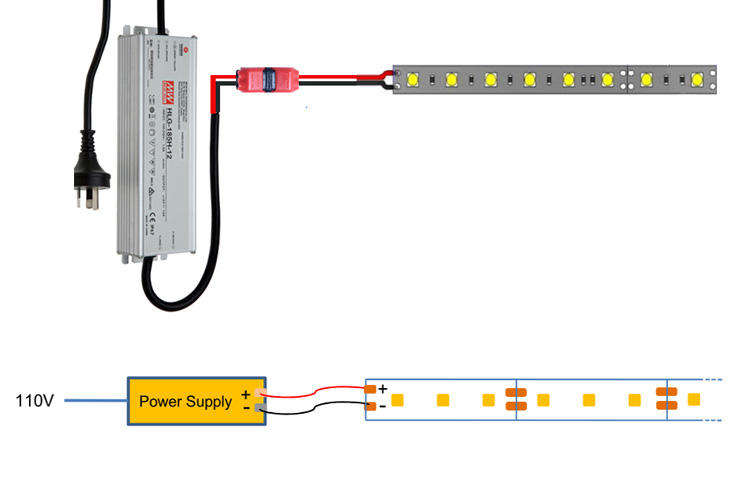

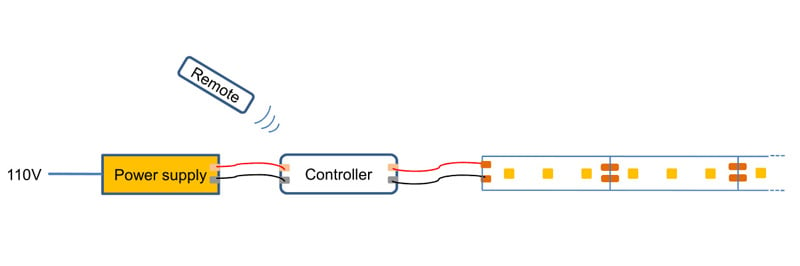

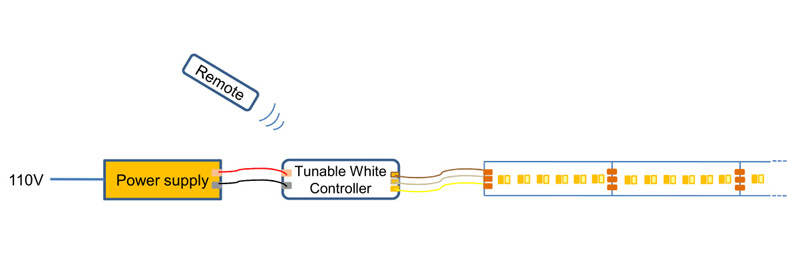

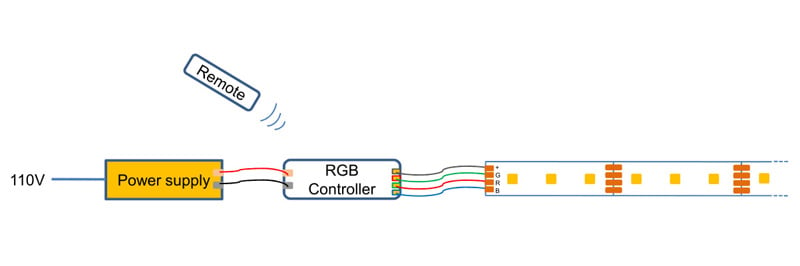

Each office of this guide can piece of work independently. If you demand to know only 1 part, you tin can spring to that part without having to read the whole commodity. Commencement Office: The Basics Preparation for LED Strip Calorie-free InstallationHere y'all will learn the strip lite installation layout. Similar to that different rooms have unlike layouts, this part explains the unlike wiring layout of strip lights, controllers, and power supplies and ability feed points appropriately. How will the wiring layout affect your project? Layout plan will directly decide the installation job, and have indirect bear upon on the price of your project. Although the light strip for a projection tin can be in a stock-still length, unlike wiring layout can outcome in unlike number of ability supplies and controllers. Hence, the price for parts and labor will be unlike. Sometimes the actual circumstance for wiring will require yous to brand selection betwixt 12V and 24V strip lights, which in turn may necessitate different ability supplies. In this sense, the cognition in this part also helps become you prepared for choosing parts later. How to connect LED strip lights to power supply?First let's take a look at the installation basic theory, and then we have an understanding for the wiring relationship among light strip, LED power supply, and LED strip controller. Simple installation1 .Connect 1 LED low-cal strip to 1 power supplyA simple installation would need an LED light strip, a proper power supply, and, in some cases, LED wires. Connect one stop of the power supply to the low voltage 12V LED strip or 24V LED strip, and the other finish to the 110V domicile electricity. Power supply should provide proper voltage and enough amperage for the lite strip. When connecting power supply to light strip, exist sure to pay attention to the polarities(+, -). Connection between incorrect polarities could damage LEDs. 12V and 24V LED strip lights are non direct wire strip lights. Practise not connect them direct to the 110V electricity. The picture below is a uncomplicated installation for one light strip and power adapter. Just need to plug DC male connectors into the female person, don't need any other connectors. As long equally it plugs in, you don't need to worry about the + or - polarity. 2. Connect two LED calorie-free strips to one ability adapterOne power adapter tin can provide power to two light strips. You only need a two-manner power splitter to connect to the two light strips. Please annotation the light strip wattage cannot exceed the output of the LED strip low-cal adapter. A power adapter is ordinarily nether 120W. Then each calorie-free strip can be 50W at well-nigh. 3. LED Strip light installation with controller.

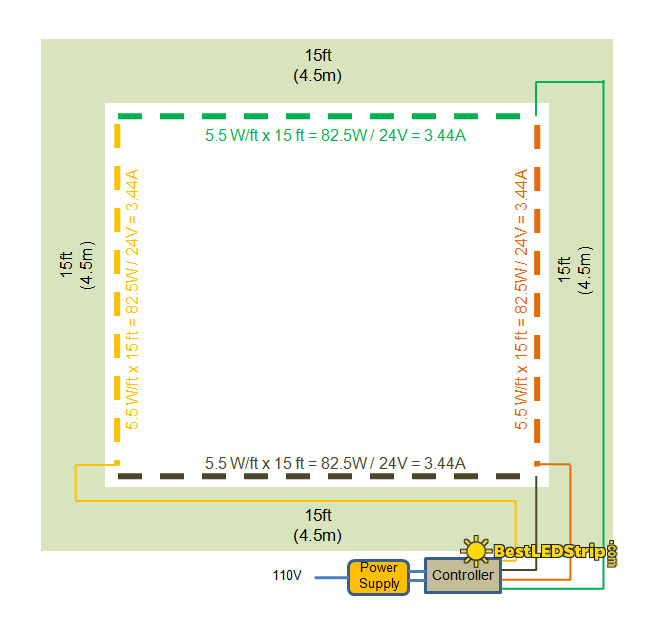

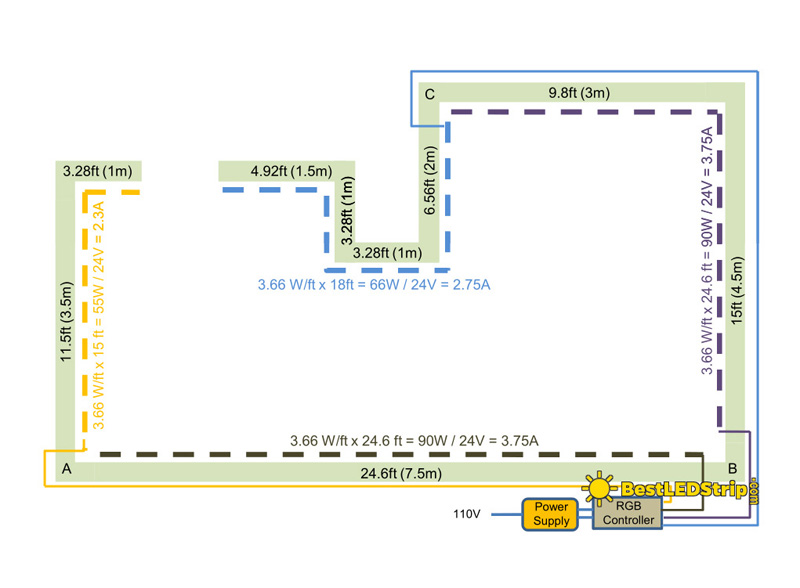

Large installation: how to connect multiple LED strips to one ability supply.In above moving-picture show, two tunable white LED strips are installed continuously and connected to ane power supply through a controller. The power is provided through two feed points. It is installed this way because voltage drop along the low-cal strip would make the rear part of the lite strip non every bit bright equally the front part. Due to the voltage drop phenomenon, strip lights are designed to a maximum operating length when powered from one stop. 12V strip lights sew to 16.4ft (5m). 24V version can be xvi.4ft (5m) or 32.8ft (10m), depending on its wattage of unit length. To put in other words, the length of a low-cal strip is related to its designed voltage, current, and wattage. 2 major factors that determine the maximum operating length of LED strip light A light strip works fine before the voltage driblet adds up to a threshold. Across the threshold, the brightness level of LEDs drops so much that it becomes noticeable to the naked eyes. The longer the light strip is, the larger the voltage drop. LED strip lights with constant electric current devices resolve the voltage drib issue, to certain degrees. The abiding current devices maintain the current steady for LEDs along the strip, then the strips can run 10m or 20m long. The type of strip lights are referred to as electric current controlled strip lights, or constant current strip lights. Just even this type of strip lights cannot exceed certain operating length due to the factor beneath. 2. Electric electric current overload. Electric current adds up forth the light strip because LED strip segments are designed to operate on parallel circuits. One segment is a cuttable unit. The flexible print excursion(FPC) lath is designed for electric current up to a limit. If the lights strip is too long(the segments are also many), the current will add up to exceed the electric current limit that the FPC lath can handle, causing current overload. Current overload volition cause too much resistive heating and hence the LED strip damage. This is besides why 12V strip lights are made for 16.4ft(5m) in length. Our current controlled strip lights are also designed up to the length nether which the strip can safely handle the electric current. The reel being sold is in the maximum length that can exist installed for a continuous run. If you desire to install longer than the designed maximum length, extra electricity feed points would exist needed. Therefore, our recommendation is to provide ability for every sixteen.4ft(5m) 12V strip lights if installed continuously. Otherwise the conductors on the low-cal strip will be adversely impacted by also large electric current menses. If you install 12V LED strips up to 32.8ft(10m), the power can be provided from the heart signal, in such a way that the light strip runs inside the 16.4ft(5m) limit on both directions. Utilize LED wire with larger current rating for this installation. How to ready LED strip lights?Here we'll explain how to ready upward LED strip lights for the situations where xvi.4ft(5m) and 32.8ft(10m) strips are used for installation. The setup or layout of installation is checked against the 16.4ft or 32.8ft dominion. The rule states: when powered from one side, a 12V or 24V light strip cannot continuously run longer than 16.4ft or 32.8ft. Beyond that indicate, the low-cal strip will have upshot of less bright LEDs and electric current overload on the strip. But indoor indirect lighting projects frequently requires installation of light strips longer than 16.4ft or 32.8ft. For example, a 15ft x 15ft (4.5mx4.5m) room has a perimeter of 59ft(18m). How to set up LED strip lights for this room? Some useful wire layout methods can resolve this issue. A common installation practice is to employ room corners as power feed points, no thing information technology is to install an extra power supply or to extend power cords from the existing power supply. Why use room corners? Information technology is because in most cases, LED strip lights cannot plough 90 degrees past themselves at room corners, and must be cutting and continued by way of soldering or using solderless LED connectors. How to wire LED strip lights.The below examples for layout LED strip low-cal installation illustrate how to wire LED strip lights in different means. The wire setup for LED strip lights explained in the examples beneath tin can exist utilized as setup guide or rules and with aligning, be used for installation for projects or rooms with different layouts. Because the unit of ability wattage for many strip lights is specified in due west/m, for your convenience, nosotros provide units in both foot and meter. The conversion rate is 1 meter = 3.28 feet. 1. A room measured 15ft x 15ft (iv.5m x four.5m). Loftier lumen output 24V LED strip lights, 5.5w/ft (18w/g). The employ of LED strip lights at ceilings as indirect lighting is an aesthetic design of primary lighting for a room. Usually indirect main lighting uses strip lights of loftier output. It is important to plan installation in such a way that every side is nether the length limit of 16.4ft(5m). For the 15ft ten 15ft (four.5m x 4.5m) room, we connect four LED wires to a controller, and extend ane LED wire to each corner of the room, with each wire continued to a 15ft(4.5m) long LED strip. This wire layout easily sets each side under the 16.4ft(5m) limit. The current load for each LED wire is 3.44A. So the layout would utilise an LED controller with four output channels, with larger than 3.44A current for each channel. Our classic LED controllers of 4x5A, 4x6A, or 4x8A have enough output power and are perfect for this installation. The strip lights we utilise have 5.5w/ft (18w/m) high lumen output, bang-up for indirect main lighting for room. Light strips connected to different channels of a controller are not to exist connected together. You desire to make sure that the channels of a controller exercise not connect ane another in any way. 2. A 11.5ftx15ft (3.v x iv.5m) room. 24V LED strip lights, medium lumen output, 3w/ft (10w/k). This is some other LED strip wire layout for indirect lighting. The strip lights have an output for 800-1000lm/grand, a medium output light strip that usually requires the maximum continuous run to be less than 16.4ft(5m). We cull the calorie-free strip with 3w/ft(10w/m). Considering the layout equally 11.5ftx15ft (3.5m x four.5m), we split the room by the diagonal line into two sections. With a long wall 15ft and a brusque wall 11.5ft, each department has a total length of 26.5ft(8m), which is longer than xvi.4ft(5m). And then we feed the strip lights from the corner where long and brusk walls meet. The maximum length of light strip powered from 1 side is 15ft along the long wall, less than 16.4ft(5m). In the above wire layout, each power feed bespeak has a current load 1.44A+ane.88A=3.32A. Current load for the whole installation would be 2 x 3.32A=6.64A. Nosotros choose a classic controller of 1 x 8A output. The controller has one channel, which can be continued with 2 LED wires from the two feed points. Or we can utilize a block terminal to connect both LED wires. iii. A room with irregular layout. The perimeter is 82ft(25m) in full, equally below. Utilise 24V RGB LED strip lights, medium output, 3.66w/ft (12w/m). With this irregular layout, we are going to plan a archetype large installation RGB strip lights. The strip is 24V, with 3.66w/ft (12w/one thousand) medium output. The maximum continuous run for this calorie-free strip is designed at 32.8ft(10m). As illustrated in the wiring layout above, we power the strip lights from three feed points: A, B, and C, with each side has a length of 15ft(4.5m), 24.6ft(vii.5m), 24.6ft(vii.5m), and 18ft(5.5m). None of them exceed the designed length of 32.8ft(10m). Because RGB LED wires are 4pin, we can split each channel of the RGB controller by using splicing connectors or terminal block connectors. Iv harnesses of 4pin RGB wire cablevision are extended from the splicing connectors and placed at the three feed points, with two harnesses being placed at signal B and ane harness at point A and C. Choose the correct RGB controller. It is important to calculate the largest electric current load at the feed points. Point B has the largest current load, 3.75A for each wire harness. Therefore, controllers of 4x5A, 4x6A, or 4x8A would work for the installation with no issue. 2d Part: The Supplies and Tools Needed for LED Strip Light Installation.In this function nosotros discuss the supplies and tools needed for LED strip lite installation, including light strips, power supply, LED controller, LED connectors and wires. Strip light aluminum extrusion profile is optional for strip low-cal heat management. Tips and guidance are provided for choosing supplies. You tin can refer to their corresponding categories for more detailed information on the supplies. 1. Cull LED strip lights(single color, tunable white, RGB, RGBW, RGB+CCT etc.) Whether it is for living room, kitchen, part or commercial spaces, LED strip lights at present can provide pleasant lighting for anywhere. The little LEDs tin can not but provide accent lighting for an area, but also tin can light the whole room beautifully. Mod LEDs are absolutely brilliant enough for whatever projects. There are many factors to be considered earlier ownership LED strip lights. For white light strips, you need choose color temperature, brightness, CRI etc. For colored calorie-free strips, in that location are ruby-red, greenish, blueish, or multi-color irresolute RGB, RGBW, RGB+CCT, etc. How to choose the best strip light for your project, delight refer to the article in the strip lights category. two. 12V, 24V power supplies, including power adapter and switch ability supply. LED power supply is also interchangeably called LED commuter, or LED transformer. Power supplies are connected to the 110V abode electricity and provide LED strip lights with 12V or 24V DC power. A proper power supply should have non just proper voltage(12V or 24V) and electric current output, but also plenty wattage to be able to ability the light strips. In order to cull a proper LED strip low-cal power supply, the wattage of the strip lights to be installed is calculated first. Formula: Strip light wattage = strip calorie-free length ten wattage/meter. The power usage of the LED strips to be installed equals LED strip'due south length times wattage per unit length. For example, for a 5m 24V LED low-cal strip, 10w/m, what ability supply should we use? The answer is 60W. The power usage for the LED strip is 5m x 10w/m = 50W. But, power supply is not supposed to be used in full load. Usually a 15-20% more capacity should exist set bated. So the ability supply should be 50w*1.2=60W. LED strips work on direct current(DC), and then simply DC power adapter or power supply tin can be used. Ac to Ac power transformers are not advisable. They will destroy LED strips. 3. LED controller. LED controller can suit brightness level, and manage LED colors. As discussed, LED controllers are optional for unmarried color strip lights, but are required for tunable white, RGB and RGBW strip lights. Do non underestimate the importance of matching capacities of dissimilar electrical parts when installing strip lights. Some users connect too long strip lights on a simple LED controller. It will damage the controller. Please use the formula below to calculate the current fatigued by strip lights: Current in amperage(A) = Full wattage of LED strips connected(W) / Voltage(V) For example, if a 18w/m RGBW LED strip is installed for 25m long, the full power adds up to 450W(when all colors and white LEDs are on full brightness). 450W divided by 24V, the current is 19A, which is virtually 5A for each channel(R ,G ,B ,and W)! For a simple controller, the current would be too large. 4. LED strip connector and LED wire. Choose the right solderless LED connectors according to the blazon and width of your LED strips. There are two important specifications when choosing LED strip connectors.

When buying LED connectors, make sure the number of pins and the width match those of the LED strip. Otherwise the connectors won't work. LED connectors are suitable for both 12V and 24V LED strip lights. Common LED types include 3528, 2835, 2216, and 5050. Although LED types are different, the strip light wiring method is similar. And so, the connectors are the same for LED strips of different LED types. During strip calorie-free installation, there are many types of connections, including strip to strip connection, strip to power supply connection, strip to controller, controller to power supply connection, etc. In general, nosotros connect through two methods: by soldering or past using solderless LED connectors.

For more information on how to choose LED connectors and LED wire, please refer to the LED connector category.

Information technology is also important to choose LED wire, which will make your installation smooth and fast. Quality LED wire should meet your installation needs, and take satisfying features such as enough current rating, well-insulated, burn down resistant etc. 5. Aluminum extrusion profile for LED strip lite installation. LED Aluminum profile is optional for installing LED strip lights. Information technology has many advantages to use aluminum profile for strip lights.

Like whatever LED lights, LED strip lights generate estrus during operation. LED is sensitive and overheat will cause decrease in its brightness equally fourth dimension goes by. Especially for development in recent years, LED strip lights accept developed higher output models to meet different needs of application. These strip lights are in special need for improve heat management. To avoid overheat, all high output LED strip lights are recommended using cooling system. Anodic oxide aluminum is the best choice. Not only it cools down LED strips, simply also its anodic oxide film can prevent possible short circuits incidentally acquired past any bare metal on LED strips. 6. Typical list of supplies and tools for strip low-cal installation.

Third Part: The Actual Steps of LED Strip Light Installation.In this office we explain the bodily steps of installing LED strip lights. The steps discussed include gear up mounting surface, measure and cut light strip, connect strips together, connect strips to controllers and power supplies, etc. It covers the practical installation cognition as well as common mistakes to avoid. Step 1. Test supplies to be installed.Before installation, it is recommended testing the supplies including LED strips and controllers. The test assures that the strip lights is ready and functional, the colour and colour temperature are what you want, the LED controllers work well and tin bring up the lighting effects yous want. Stride 2. Gear up mounting surfaces.Well-prepared mounting surfaces will facilitate fast and secure mounting of strip lights. To obtain optimum adhesion, the mounting surfaces or bonding surfaces must be clean dry and well unified. Surface preparation includes removing dirt, oil, and other contaminates. A typical surface cleaning solvent is isopropyl alcohol(IPA) based solution, 70% IPA and 30% water. For oily substrate, use acetone instead of IPA. Employ proper safety precautions for handling solvents. Utilize adhesion primer to promote stronger bond. In some cases, abrading the substrate surface can help remove oil layers and other contaminates. While waiting for the prepared surfaces to dry, we can continue onto next steps. Step three. Measure length.Previously, in the first office when planning layout of strip light installation, you may accept measured the full length of light strips needed. Now nosotros demand measure out the length for each leg of installation. Equally mentioned before, most times the strip lights need to be cut where information technology makes turns. Accept notes of your measurements as you will demand them when cutting LED strips subsequently. Step iv. How to cut LED strip lights?Cutting LED strips is the easiest thing. Anyone who tin can utilise a pair of pair of scissors can do it. Cutting lines are marked past each cuttable segments on LED strips. Most common LED strip lights can be cut every three or six LEDs. Our 5050 white strip lights are particularly designed to be cuttable in very short increments, every LED or every two LEDs. The short cutting increments are perfect for accurate length of installation. Cutting should exist exactly along the cut line, which ensures both cutting ends of the strip have enough size of copper pads. Copper pads work as soldering base for soldering connectedness, or as connection points for solderless LED connectors. Every bit you cut, you can clearly come across the electrical polarity marks + and - for unmarried colour strip lights. For tunable white, RGB and RGBW strip lights, the marks are normally positive mark + and color marks, G(Green), R(Red), B(Blue), WW(Warm white), CW(Cool White). The colour marks are negative polarities. + and - on single color LED strip lights + and color marks on RGB LED strip lights Footstep five. How to connect LED strip lights together?Connect linkable LED strip lights mainly for making 90 degree turns or straight strip to strip connections. 90 caste turn connections are mutual for corner installation. 1. Fast solderless LED connectors. LED strip lights can be fast connected using solderless connectors. To employ LED strip to strip connectors:

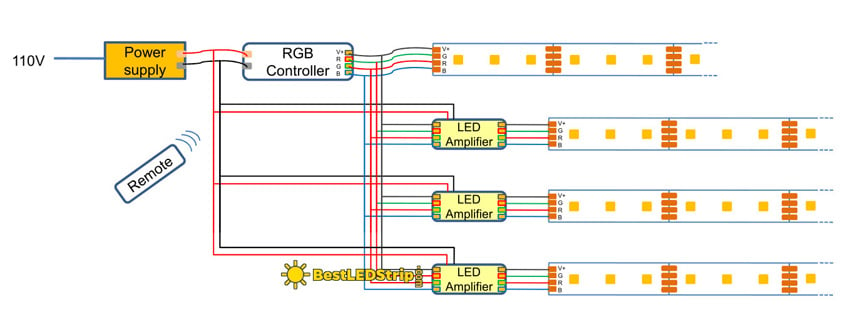

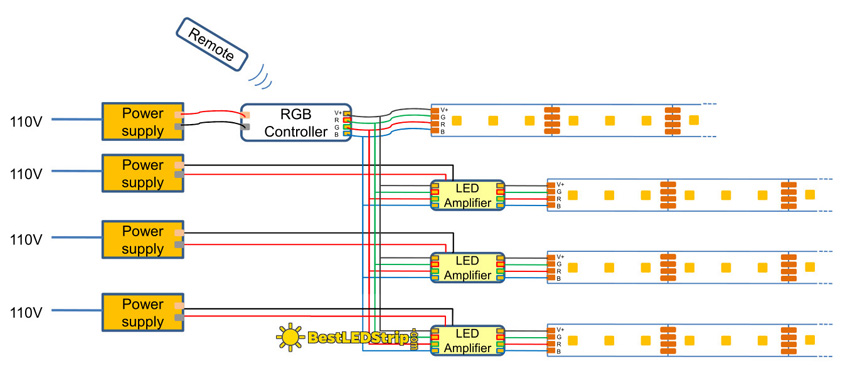

two. Repeat the to a higher place steps to connect another strip on the other end of the connector. Please make certain the polarities match correctly for light strip and connector. Incorrect polarity connectedness can cause harm to strip lights and connectors. 3. Where low-cal strips need to make turns, don't twist LED strip. If there is trouble making turns, information technology is ameliorate to cut off the light strip and use flat and short LED connectors to make turn connections. 4. Soldering is sometimes necessary to connect strip lights together, especially when there is difficulty using solderless connectors. When y'all cannot detect a suitable connector, y'all can make a professional connection by soldering. Solder connectedness is more aesthetic. 5. Specialty waterproof strip connectors are designed for quick connecting waterproof strip lights(IP65, IP67, IP68). Step half-dozen. How to connect LED strips to power supply?For unmarried color strip lights, you lot can connect LED strips to ability supply directly, connecting V+ to V+, 5- to V-. Must pay attention and correctly match the electrical polarities. Wrong polarity connection can destroy the strip lights. Optionally, an LED dimmer can exist place between LED strip and power supply to adjust strip brightness level. It is easier to connect power adapter to LED strip. Both have a coaxial DC connector. Just plug the male person DC connector with female DC connector. For more data on how to connect ability adapter to light strip, please refer to the ability adapter category. Connect RGB LED strip to RGB controller.RGB LED strips must operate with the help of RGB controller, which takes care of the color management function. Connecting RGB strip lights to controller tin can be done in different means, depending on the type of RGB controller. Ane blazon of controllers have wire connecting terminals, marked with +, G(green), R(carmine), B(blue), like to the marks on RGB strip lights. In this example, wire the RGB LED iv pin cable to the terminals, positive wire to terminal +, G wire to terminal K, R wire to terminal R, and B wire to terminal B. And then we connect RGB controller to ability supply by ability cable or DC connector. The positive cablevision of power supply connects with positive input last on the controller, and the same with negative connection. Another type of RGB controllers take iv pin connectors. Its connection with RGB strip lights is like shooting fish in a barrel, by joining the 4 pin connectors on the controller with the 4 pin connector on low-cal strip together. How to connect LED strip lights in series?LED strip lights are designed to run continuously up to a sure limit due to voltage drop and electric current load issues. This limit put challenges for connecting LED strip lights in serial to reach longer installation. In former parts we create some example wiring layouts to work around the issues. Now we accept a wait at the actual wire connections. We use RGB strip low-cal installation as example considering information technology is the most complicated among the strip low-cal installations. RGB strip lights are ready to run xvi.4ft(5m) or 32.8ft(10m). For longer RGB strip light installation, RGB LED amplifiers are used to amplify control signals. Below are wiring illustrations for installation with RGB controller and amplifier. For installation in higher up illustration, RGB controller and LED amplifiers are wired to the same ability supply. Every bit installation in above wiring layout, RGB controller and LED amplifiers are wired to different power supplies. Pace vii. How to power LED strip?Connecting LED strip light to mains is washed through connecting strip light to LED power supply then to the 110V home electrical organisation. Actually it is the power supply that directly provides power to LED strips. The input terminals for power supply are marked with L, N, G, with L for live wire, Due north for neutral wire, and Thou for basis wire. Ground concluding is often marked with grounding symbol. Through the three power wires Fifty, N, G, power supplies are connected to electric organization. Pace 8. Test the connections.Previous to mounting LED strips, it is very important to examination all the connections we made in previous steps. The test is to brand sure all the connections work well, preventing surprise after nosotros mount the strip lights. After the LED strip is practical with 3M adhesive tape, it would exist very difficult to accept information technology down. Even yous managed to do and then, the LED strip may have potential damages caused by stress during taking it downward. In addition, you would not be able to establish a secure bonding if you lot employ the 3M adhesive tape for the 2nd time. Pace 9. Mount LED strip lights, controller and power supply.How to hang LED strip lights?There are two ways to mount LED strip lights. One mode is to utilize 3M double-sided tape, and the other way is to employ mounting brackets. 9.one Peel and stick installation by using 3M tape. Application of the light strip two feet a time can forbid the light strip from being messed up by entangling themselves or sticking to grit etc. Tips: using a file cleaner to pare off the release liner of 3M record is very helpful if you demand to skin off a lot of times. To avoid applying likewise much pressure on LEDs when sticking the LED strip. The amount of adhesive-to-surface contact developed has direct affect on bond strength. Firm application force per unit area develops better adhesive contact and thus improves bond forcefulness. Merely don't press too hard, especially on LEDs and resistors. Pressure should be simply applied on the areas where there are no LEDs or other electrical components. A big rubber pad like eraser can exist helpful. 9.ii Using strip mounting brackets. It is also often used for indoor applications where LED strips are subconscious or invisible, like ceiling cove lighting. It could exist hard to fix awarding surface full of dust for extended length on the ceiling coves. Furthermore, the mounting brackets won't cake the lights from LEDs. Last, mountain the LED controller and power supplies. Turn on the ability, and enjoy your strip lighting! After reading this LED strip installation guide, you tin install strip lights like a professional person now. Should yous accept any other questions, please practise not hesitate to contact usa. We are e'er here to assistance you. |

Source: https://www.bestledstrip.com/how-to-install-led-strip-lights

Posted by: chambleefeativill.blogspot.com

0 Response to "How To Install Waterproof Led Strip Lights"

Post a Comment